Description

12,000L/H Vacuum Transformer Oil Degassing Process Plant

DVTP Transformer Oil Purification Plant will purify,dry and de-aerate oil to ensure dielectric strength and insulating properties of oil is restored.

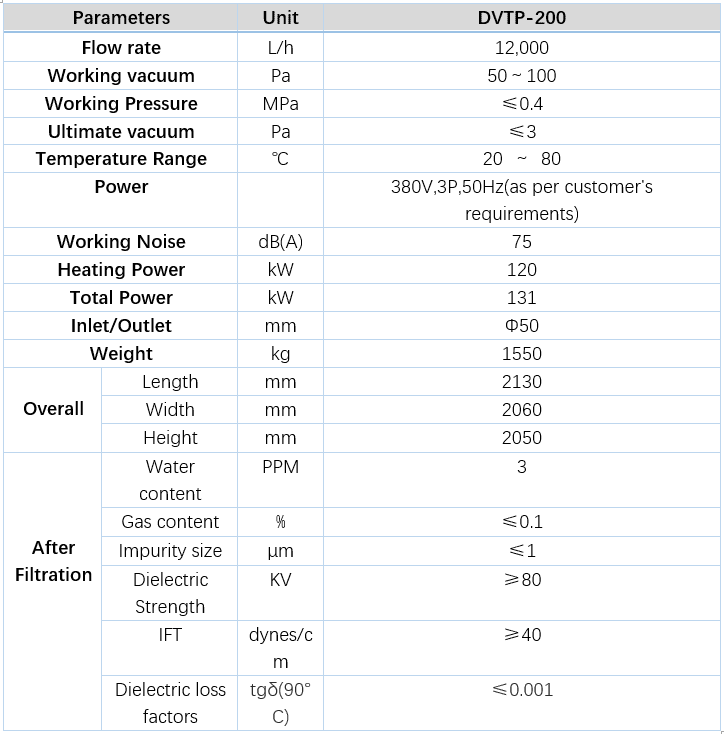

Technical Parameters

Parameters | Unit | DVTP-200 | |

Flow rate | L/h | 12,000 | |

Working vacuum | Pa | 50~100 | |

Working Pressure | MPa | ≤0.4 | |

Ultimate vacuum | Pa | ≤3 | |

Temperature Range | ℃ | 20 ~ 80 | |

Power | 380V,3P,50Hz(as per customer’s requirements) | ||

Working Noise | dB(A) | 75 | |

Heating Power | kW | 120 | |

Total Power | kW | 131 | |

Inlet/Outlet | mm | Φ50 | |

Weight | kg | 1550 | |

Overall | Length | mm | 2130 |

Width | mm | 2060 | |

Height | mm | 2050 | |

After Filtration | Water content | PPM | 3 |

Gas content | % | ≤0.1 | |

Impurity size | μm | ≤1 | |

Dielectric Strength | KV | ≥80 | |

IFT | dynes/cm | ≥40 | |

Dielectric loss factors | tgδ(90°C) | ≤0.001 | |

Usage

ASSEN DVTP Transformer Oil Degassing Process Plant maintains and extends the life of the transformer.

Filtered and dried oil is required for transformers. The insulating oil absorbs moisture and is polluted by sopping fibers, dirty particles, aging products, and soot while in use. Even unused oil may have absorbed moisture from the air or become polluted in the barrel in which it was stored. As the moisture level rises, the efficiency of oil as an insulator decreases dramatically. As a result, transformer oil degassing process is a critical process that removes solid particles, dissolved gases, and dissolved water. Filtering, dehydration, and degassing can improve the electrical properties of the oil.

Technial Features

A). Interchangeable Inlet & Outlet

A design that can switch oil inlet and oil outlet without changing the connecting hoses.

B). Optional Online PPM Meter, Optional digital flow meter with accumulator function.

C). Advanced automatic thermostat control system, automatic liquid level control system, automatic defoaming control system, and automatic pressure protection system to ensure high-performance operation of the equipment.

D). All kinds of protection in the design, sensitive automatic pressure protection system and infrared liquid level control system, oil and heating interlocking safety protection system.

1.Capable of reducing moisture content from 50ppm to 3ppm and gas content from 12% to less than 0.1% by volume. Particulate matter will be removed in 98% of cases.

2. Double-Stage vacuum system,strong power of vacuum evacuating,ultimate vacuum value no more than 5Pa

3. Duplex-Stereo film evaporation technology,combined with unique and advanced dewatering,degassing components,can rapidly and effectively separate water, gas,from oil.

4. An advanced fully automatic temperature controlling system,liquid-level controlling system,defoaming controlling system,pressure protecting system and excellent configuration can ensure operation of the equipment with high performance

5. Online work,allowing separated operation of manual operators from machine with lamps indicating the condition for operation.

6 It is humanization design with low noise,deep purification and long time free maintenance to save cost from the running process.

Optional Model

1.) Optional P.L.C. intelligent panel control, touch screen operation and dynamic display according to user needs.

2.) Optional Online PPM Meter, Optional flow meter with accumulator function.

3.) Optional Flow Converter, you can adjust the flow according to your needs

4.) Optional external port design for transformer vacuum pumping

5.) The whole structure can be made into mobile, fixed, fully enclosed, concealed, canvas, open type.

6.) Optional three stage high vacuum system for higher vacuum degree work.