Description

By using the ASSEN Lube Oil Purifier machine you will benefit from the following:

- Reduced machine downtime

- Less equipment maintenance

- Extended lubricating oil life

What does a lube oil purifier do?

1. Strong impurity removal ability. large area and deep precision filter can remove fine particles in the oil.

2. Multi-stage cylinder filter, large flow, and washable filter element ensure the high filtration efficiency. Due to the use of step-by-step encryption technology, the serious pollution of lubricating oil can be purified to the qualified standard. The designed auto backwash system can automatically clean a large number of impurities in the filter.it not only improves the continuous working time of the equipment but also extends the life of the filter.

3. Advanced medium heat absorption and condensation system.

4. Automatic temperature control and heating, automatic separation of condensate water device, simple operation, safe and reliable.

5. Super emulsifying ability, not only separate a large amount of water in the oil, but also remove the trace water in the oil

6. Combined with coalescence, separation and vacuum dehydration, the water separation device adopts coalescence and separation technology, which can quickly separate a large amount of water and moisture from the lubricating oil with high water content.

7. Deep and high-precision FH rectangular filter system can effectively remove iron filings, dust and impurities in the oil.

8. Self-developed H, P, M polymer material filtration technology.

9. Adopt high quality original components and connecting sealing materials to meet the requirements of high viscosity lubricating oil filtration with high temperature, and expand the type and range of oil that can be purified by the oil filter.

10. Adopt high-quality filter material which can contain a large number of stains. It also guaranteed high corrosion resistance, temperature resistance, excellent mechanical strength, high accuracy in the removal of impurities, and long service life.

11. Humanized designed double infrared liquid level control system, with phase sequence protection, overload protection, and over-voltage protection of the electrical automatic protection control system.it also adopts with constant temperature automatic control system, to ensure that the operation is simple, safe, and reliable. The machine can work online for a long time, unique oil pump, low noise, in line with the world’s high standards of environmental protection requirements.

Introduction

Hydraulic oil contaminated by water, gas, impurities will affect the lubrication system of machines and equipment, ASSEN TYA Lube Oil Purifier machine has the perfect capability of removing impurities, mass, and deep precision purification material from lubrication oil and improving properties of lubricating oil so as to greatly extend the lifetime of machinery. TYA lubricating oil purification plant is also equipped with a permanent magnet filter to filter ferruginous impurities..

Lube Oil Purifier's Features

- Unique water/gas removal system,which adopts stereo-evaporating technology,multi-oil water separation technology,enabling fast removal of water,and gas in the oil

- Optimazed electric heating system withautomatic constant temperature controller ensures that oil temperature to be even and stable

- An advanced fully automatic temperature controlling system,liquid-level controlling system,defoaming controlling system,pressure protecting system and excellent configuration can ensure operation of the equipment with high performance.

- Online work,allowing separated operation of manual operators from machine with lamps indicating the condition for operation.

- Perfect auto protection device ensure the plant can continuous work without people, It is a low maintenance cost and best economic benefit machine

Technical Parameters

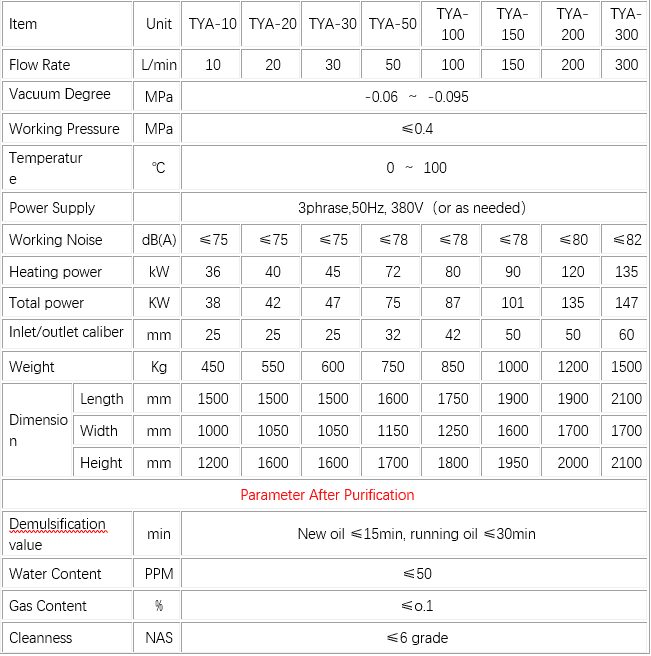

| Item | Unit | TYA-10 | TYA-20 | TYA-30 | TYA-50 | TYA-100 | TYA-150 | TYA-200 | TYA-300 | |

| Flow Rate | L/min | 10 | 20 | 30 | 50 | 100 | 150 | 200 | 300 | |

| Vacuum Degree | MPa | -0.06 ~ -0.095 | ||||||||

| Working Pressure | MPa | ≤0.4 | ||||||||

| Temperature | ℃ | 0 ~ 100 | ||||||||

| Power Supply | 3phrase,50Hz, 380V(or as needed) | |||||||||

| Working Noise | dB(A) | ≤75 | ≤75 | ≤75 | ≤78 | ≤78 | ≤78 | ≤80 | ≤82 | |

| Heating power | kW | 36 | 40 | 45 | 72 | 80 | 90 | 120 | 135 | |

| Total power | KW | 38 | 42 | 47 | 75 | 87 | 101 | 135 | 147 | |

| Inlet/outlet caliber | mm | 25 | 25 | 25 | 32 | 42 | 50 | 50 | 60 | |

| Weight | Kg | 450 | 550 | 600 | 750 | 850 | 1000 | 1200 | 1500 | |

| Dimension | Length | mm | 1500 | 1500 | 1500 | 1600 | 1750 | 1900 | 1900 | 2100 |

| Width | mm | 1000 | 1050 | 1050 | 1150 | 1250 | 1600 | 1700 | 1700 | |

| Height | mm | 1200 | 1600 | 1600 | 1700 | 1800 | 1950 | 2000 | 2100 | |

| Parameter After Purification | ||||||||||

| Demulsification value | min | New oil ≤15min, running oil ≤30min | ||||||||

| Water Content | PPM | ≤50 | ||||||||

| Gas Content | % | ≤o.1 | ||||||||

| Cleanness | NAS | ≤6 grade | ||||||||