Description

What is a vacuum oil purification?

Wikipedia gives a good explanation, Oil purification (transformer, turbine, industrial, etc.) removes oil contaminants in order to prolong oil service life.

Why need vacuum lubricating oil purifier?

One of the primary causes of engine lubricating oil deterioration is oxidation, and lubricating oil oxidation products pose the following risks to the engine.

- The acid produced by lubricating oil oxidation will corrode the metal parts.

- After lubricating oil oxidation, oil insoluble deposits form. This can easily clog the lubrication system’s oil circuit and oil filter, causing damage to the lubrication cycle and increased wear.

- Oxidation deposits form on valves and in piston ring grooves, causing valves to burn and piston rings to bind, causing them to lose elasticity and increase lubricant consumption.

In short, the accumulation of oxidation products in the lubricant will cause significant changes in the lubricant’s appearance and physicochemical properties. The oil’s color shifts from light to dark, or even black. The oil’s viscosity rises, its acidity rises, and deposits frequently form.

How is the lubricating oil purified?

The goal of lubricating oil purifier machine is to control the size and number of mechanical particles per unit volume for the lubricant’s properties. To achieve a NAS6 or higher level of cleanliness.

The oil is drawn into the system and is passed through the Primary Filter(>30 micron). by the use of the vacuum created by the system’s vacuum pump. Then the oil flows through the Heater, where the oil temperature is raised to a preset degree.

Since lubricating oil usually contains severe water contamination, it need be guided to the Coalescence & Separation Filters where large volume of free water is rapidly removed. After that, the oil enters into the Vacuum Chamber, in which emulsified and dissolved waters and gasses contained in the oil are thoroughly exposed to vacuum by efficient dispersion and removed through a Vacuum Pumping.

TYA Lubricating Oil Purifier Functions

- Strong demulsification ability. The average demulsification time is within 15 minutes

- High-precision filtration can effectively remove impurities smaller than 1μ. After several times of filtration, the cleanliness of the oil can be stably maintained at the NAS1638 6 level without block.it is suitable for precision hydraulic systems.

- Reducing equipment error and losses of shutdown, save the maintenance cost.

- Greatly extend the life of oil, reduce 90-99% production of waste oil, and protect the environment at the same time.

- Perfect auto protection device ensure the plant can continuous work without people, It is a low maintenance cost and best economic benefit machine.

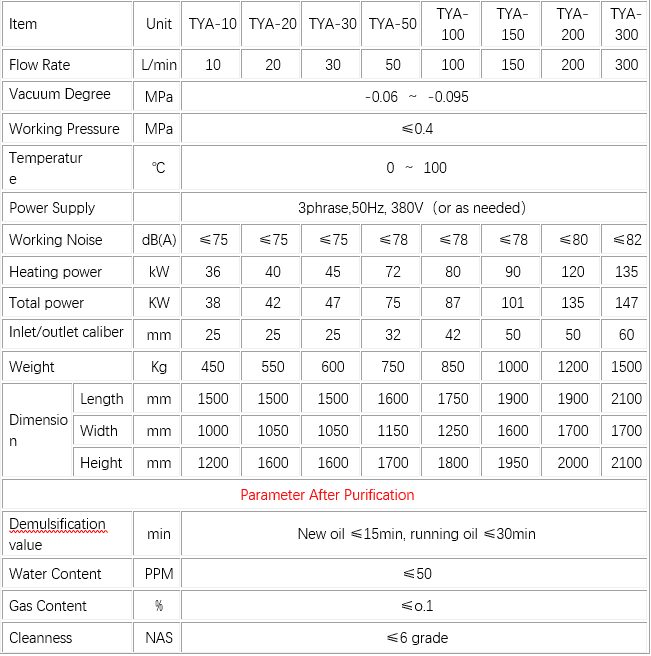

Technical Parameters

ASSEN's Advantages

1. Advanced medium heat absorption and condensation system.

2. Automatic temperature control and heating, condensate water separation device, simple operation, safe and dependable.

3. The oil’s super emulsifying ability not only separates a large amount of water but also removes trace water.

4. The water separation device, when combined with coalescence, separation, and vacuum dehydration, can quickly separate a large amount of water and moisture from lubricating oil with a high water content.

5. The FH rectangular filter system can effectively remove iron filings, dust, and impurities from oil.

6. H, P, M polymer material filtration technology developed in-house.

7. Adopt high-quality original components and connecting sealing materials to meet the demands of high-viscosity lubricating oil filtration at high temperatures, and broaden the type and range of oil that can be purified by an oil filter.

8. TYA lubricating oil purifier machine use high-quality filter material that can hold a large number of stains. It also ensured high corrosion resistance, temperature resistance, excellent mechanical strength, impurity removal accuracy, and long service life.

9. Humanized designed double infrared liquid level control system, with electrical automatic protection control system phase sequence protection, overload protection, and over-voltage protection. It also adopts a constant temperature automated control system, to ensure that the operation is simple, safe, and reliable. The machine can operate for an extended period of time, has a unique oil pump, produces little noise, and meets the world’s high environmental protection standards.

ASSEN Vacuum Lubricating Oil Purifier Machine