What is transformer oil purifier?

Transformers are important devices therefore increasing the importance oil. Transformer oils are lost quality in time. Consisting of moisture in the oil causes sludge and acid after a short time with a oxidation of air. DVTP Transformer Oil Purifier Machine is mainly used to improve the properties of insulation oil. It can remove trace water, gas, particulates, and other harmful matters etc. from the insulating oil effectively and rapidly so as to boost performance of transformers, circuit breakers, mutual inductors, cable and capacitors which has insulation system.

What is the use of transformer oil filtration?

-degassing & dehydrating mode(Removes gas, water, impurities and other contaminants from transformer oil,Improves oil dielectric strength up to 75KV)

-regeneration mode(Remove acidity, sludge, free carbon, other soluble oil decay products and discoloration)

-eliminating organic acid, sludge, pitches and dissociated carbon in the deteriorated insulating oil.

-heating & filtration mode

-vacuum pulling mode

-transformer evacuation mode(Extends transformer life, ensures safety operation of oil-filled transformer)

How often should transformer oil be filtered?

According to the testing specifications of transformer oil, the transformer oil in operation should be tested for oil quality analysis every time, and whether it is necessary to replace the transformer oil is considered according to the results of the testing and analysis or the operating state.

According to the service life of the transformer, through the latest comprehensive analysis of the transformer oil insulation resistance, absorption ratio, polarization index, dielectric loss, winding leakage current, slight water in the oil, etc., comprehensively judge the moisture condition, impurities, oil aging, etc. If it is not qualified, you need our DVTP Transformer Oil Purifier Plant for oil purification and continue to use. If it is not available for oil regenerate in special circumstances, you can also consider replacing with new transformer oil.

Generally speaking, dissolve gas analysis of transformer oil needs to be done annually for 132kV transformer, once in 2 years for the transformer below 132kV transformer, and once in 2 years for the transformer above 132kV transformer.

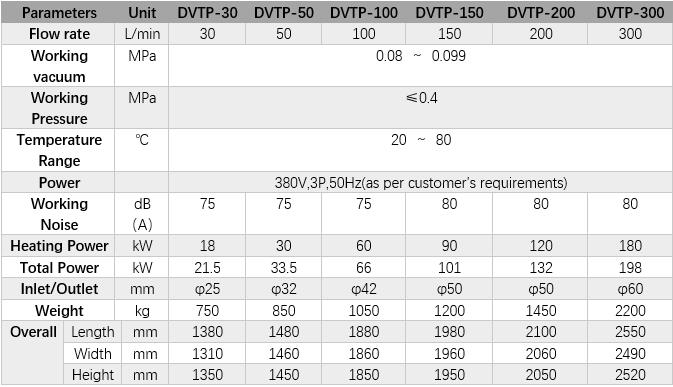

Technical Parameters

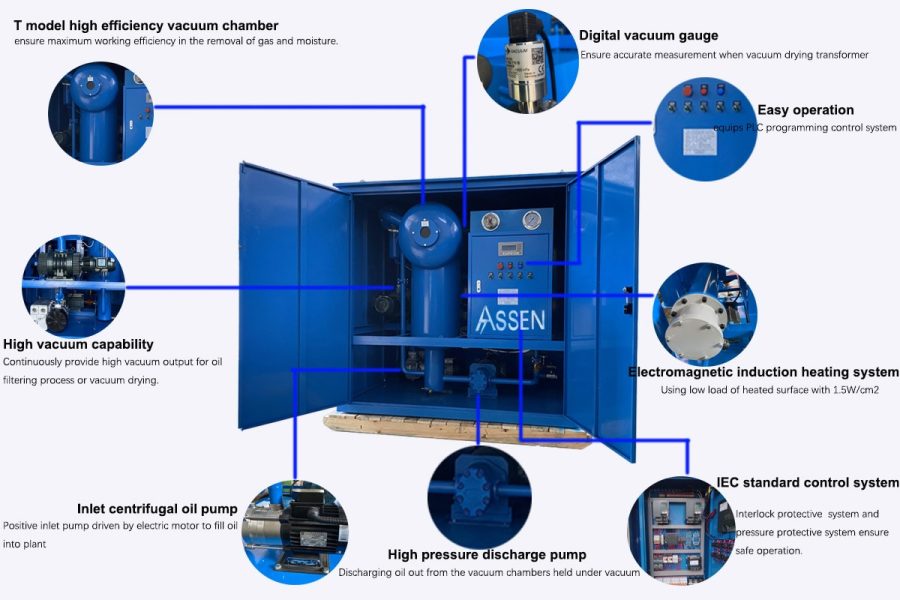

Features

1.Dehydration, degassing, and impurity removal of 110-1100KV main transformer insulation oil

2.Double-Stage vacuum system, strong power of vacuum evacuating, ultimate vacuum value no more than 5Pa

3.Duplex-Stereo film evaporation technology, combined with unique and advanced dewatering, degassing components, can rapidly and effectively separate water, gas, from oil.

4.An advanced fully automatic temperature controlling system,liquid-level controlling system, defoaming controlling system, pressure protecting system, and excellent configuration can ensure operation of the equipment with high performance

5.Online work, allowing separated operation of manual operators from the machine with lamps indicating the condition for operation.

6.It is a humanization design with low noise, deep purification, and long-time free maintenance to save cost from the running process.

ASSEN warrants the plant supplied under this specification against defects in material and workmanship under normal use and service for a period of twenty-six (26) months from the date of shipment or twenty-four (24) months after the start-up of the system. ASSEN’s obligation under this warranty is limited to repairing or furnishing, a similar part to replace any part, which was proven to be defective within the warranty period.

1.We customize the machine to your requirements.

2.We have more than 20 years of export experience.

3.We offer our customers high-quality products at a competitive price.

4.We offer our customers excellent after-sales service.

5.We are not satisfied until our customers are satisfied.

REQUEST A QUOTE

Fill all information details to consult with us to get sevices from us