DVTP PLC Dielectric Oil Dehydration and Reclamation Plant, Both auto and manual modes, Safe and Easy Operation.

Introduction

Moisture is one of the most important contaminants that affect the performance of the dielectric fluid and ultimately affect the life of the transformer. ASSEN PLC Fully Automatically high vacuum dielectric oil dehydration and reclamation unit combines unique advanced vacuum dehydration, degassing components and three-stage filtration system to quickly and efficiently separate water, gas, particles and oil to restore the performance of insulating oil.

DVTP Dielectric Oil Dehydration Plant equips Italy SEIM Screw oil pump, this gather benefits such as very low noise level, very low pulsation into the pumped medium, eliminate the production of acetylene gas, very perfect performance and long life.

Technical Features

1.Expectations on an effective oil plant for treatment of insulating oil.

2.PLC mode,Easy and failsafe operation.

3.On-line measuring and recording of process parameters.

4.It is equipped with leakage and overload stop devices to protect the motor

5.Fast and efficient extrusion of moisture, gas, machinery impurities in the oil, and other harmful substances, improve the insulating oil flash point and breakdown voltage.

Principle of DVTP Dielectric Oil Dehydration Plant

Insulating oil is drawn into the system and is passed through the primary filter by thenegative pressure generated by the Vacuum System or supplementary feeding pump.Then the oil flows through the heaters, during which the oil temperature is raised to apreset degree.

After passing the secondary filter, the heated oil then enters into the Vacuum Dehydration/Degasification Chamber, where water and gasses contained in the oil arethoroughly exposed under vacuum by efficient dispersion and removed through a Vacuum Pumping.

ASSEN® dielectric oil dehydration and purification system unit use parallel sprayers inside the Vacuum Chamber for the maximumexposure of oil to the effect of vacuum. The sprayer design has created a great efficiencyin cutting oil into tiny droplets, thus greatly improve dehydration and degasification.

The oil is then discharged by a screw pump through a high efficiency filter element where a fine polishing of oil takes place. After passing through the Fine Filter, the purified oil exits through the outlet or flows via the re-circulation valve to be processed again.

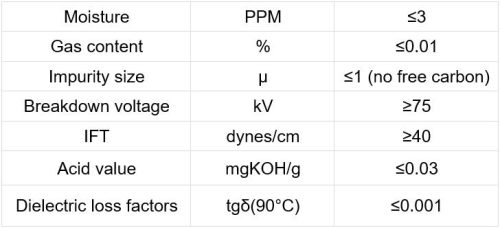

After treatment, the oil parameters are as following

- Your inquiry related to our products or prices will be replied to in 24 hours.

- Well-trained and experienced staff to answer all your inquiries in fluent English.

- Professional service from the well-trained and experienced staff is customers’ best choice to secure good communication, on-time delivery, reliable warranty, etc.

- OEM is available for ASSEN Products.

- Protection of your sales area, ideas of design, and all your private information.