As we all know, transformer oil is an insulating oil product with strict moisture requirements, because a small amount of water can reduce the withstand voltage performance of transformer oil, and the dielectric loss will increase, resulting in transformer failure. Therefore, the moisture content of ordinary transformer oil and special transformer oil (ultra-high voltage) should be controlled at 30~40mg/kg (ppm).

In this regard, let's analyze the trace moisture in transformer oil and other possible conditions of transformer oil during use.

1).A transformer in operation rarely requires moisture determination. Commonly used oil-immersed transformers (and air-cooled transformers, generally small transformers) have their iron cores and coils immersed in oil, and the entire transformer including the heat dissipation part is a completely closed system. The entire system is filled with oil, leaving only a small amount of space for the oil to expand and contract. For this reason, transformer oil usually does not come into contact with air and water. The operating transformer oil basically has the same life as the transformer. Unless, in the event of faulty electricity, heat (instantaneous strong electricity, high temperature) or equipment overhaul, the transformer is replaced with parts, and the oil is changed at the same time. Therefore, the transformer oil in operation requires little or no moisture measurement.

2). Analysis of the causes of transformer oil aging. It is more appropriate to say that the deterioration and decay of transformer oil is simply caused by oxidation, but it is more appropriate to say that it is caused by aging. The aging process of transformer oil refers to the change of color, odor, viscosity, acid value and dielectric loss of transformer oil under the action of light, heat, oxygen, arc, electric field, magnetic field, radiation and other physical and chemical factors. The process of the decrease or deterioration of its dielectric properties is a complex physical and chemical process. The process can be divided into two types: thermal oxidative aging and electrical aging.

(a). Thermo-oxidative aging means that the transformer oil is oxidized when exposed to light, heat, radiation and active substances such as oxygen or oxidizing gas; Leads to the aging of transformer oil. Light and radiation can promote the aging of transformer oil. Light and radiation give oil molecules a certain amount of energy, activate oil molecules, and contribute to the aging of oil. It can cut off the molecular chain so that the viscosity of the insulating oil changes, the oil becomes turbid, and at the same time, suspended solids and precipitates are generated. Under the action of light, heat and radiation, the free radical chain reaction of auto-oxidation occurs inside the transformer oil, producing acidic substances, resulting in an increase in the acid value. Thermo-oxidative aging is a vicious cycle process. The result is that the color of the transformer oil becomes darker, the viscosity becomes larger, the acid value increases, the water-soluble component becomes larger, the electrical conductivity increases, the insulation becomes worse, the dielectric properties decrease significantly, and the oxidation is stable. Deterioration and corrosion of metal parts of equipment.

(b). Electrical aging means that the transformer oil is always in a changing electric field when it is used. For long-term use, the action of the electric field will cause the transformer oil to gradually decay and deteriorate, and at the same time produce many non-ideal components, such as acidic substances and weakly alkaline substances. . Due to the effect of electricity and heat, especially in the case of strong over-electricity and overheating, the carbon-hydrogen bond (C-H) and carbon-carbon bond (C-C) of the transformer oil molecules can be broken, accompanied by the generation of a small amount of active hydrogen molecules and unstable The free radicals of hydrocarbons, these hydrogen atoms and low molecular hydrocarbons may produce hydrocarbon polymers and solid carbon particles with different electrical failure times. Ultimately affect the normal use of the transformer. There are many kinds of aging evaluations for transformer oil, but electrical aging evaluations are rare. The Analysis Center of Sinopec Lubricating Oil Co., Ltd. Shanghai Branch is equipped with the only transformer oil bench evaluation equipment in the country that was used for evaluation or arbitration. It simulates the transformer oil in operation and is especially suitable for evaluating its electrical aging performance.

3).The state and harm of micro water in transformer oil. During transportation, storage and use, the transformer may enter from the outside world or absorb water from the oil, and the generated water will exist in the following states: First, free water. Most of the water invaded by the outside world, if it is not stirred, it is not easy to combine with water. It does not affect the breakdown voltage of the oil, but it is also not allowed, indicating that there may be dissolved water in the oil, which should be dealt with immediately. The second is that extremely fine particles dissolve in water. It usually enters the oil from the air, which drastically reduces the breakdown voltage of the oil. If the medium loss increases, the oil should be vacuum filtered. The third is emulsified water. Poor refining of oil, aging of oil due to long-term operation, or contamination of oil by emulsions will reduce the interfacial tension between oil and water. If oil and water are mixed together, an emulsified state will be formed. Its hazards: First, reduce the breakdown voltage of oil products. The breakdown voltage of 100-200mg/kg is greatly reduced to 1.0kV. The fiber impurities in the oil can easily absorb water. Under the action of the electric field, a conductive “bridge” is formed between the electrodes, so it is easy to break down. The second is to increase the dielectric loss factor. Suspended emulsified water has the greatest effect and is not uniform. The third is to promote the aging of insulating fibers. The molecules of insulating fibers are glucose (C6H12O6) molecules. After moisture enters the fiber molecules, its gravitational force is reduced, and it is hydrolyzed into low-molecular substances, reducing the mechanical strength and degree of polymerization of the fibers. Experiments have shown that at 120 ° C, the mechanical strength of the fiber decreases by 1/2 for each increase of the moisture in the insulating fiber. When the temperature increases, the water in the oil increases, the water in the fiber decreases, and the temperature decreases, and vice versa. Therefore, the trace water in transformer oil should be monitored and the aging of the insulating fibers should be monitored. Fourth, moisture promotes the corrosion ability of organic acids and accelerates the corrosion of metal parts.

To sum up, the more trace water in transformer oil, the faster the aging of the oil itself, the aging of equipment insulation and the corrosion of metal parts. Therefore, it is necessary to monitor the content of water in the oil, especially the content of dissolved water. Of course, the main focus of control and detection of micro-moisture in transformer oil should be after filling and before installation of transformer oil. After all, the transformer oil in operation is in a closed body, and water molecules from the outside are not easy to enter.

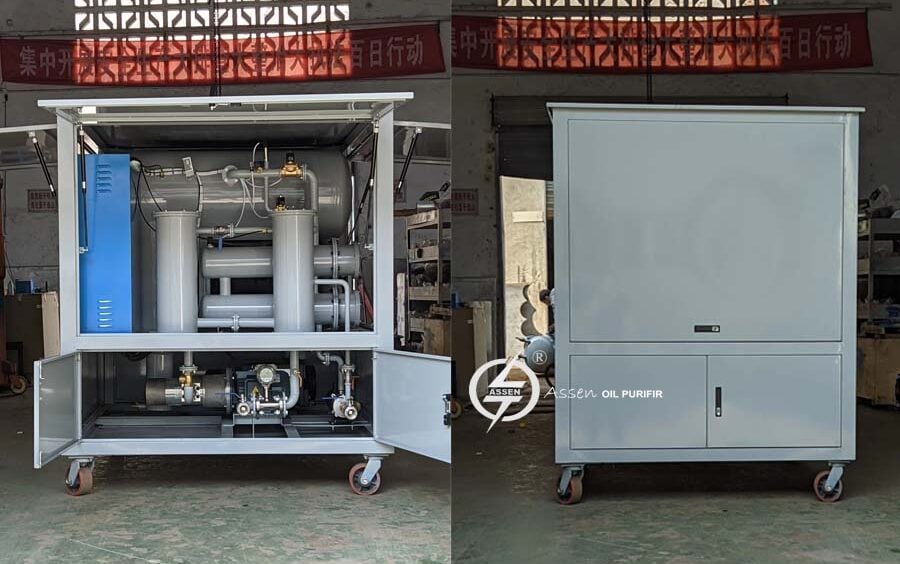

ASSEN’s DVTP series High Vacuum Transformer Oil Purifier has powerful vacuum system, and can remove trace water and moisture from insulating oil very efficiently.

If you want to measure trace moisture in transformer oil, Online moisture detector can be installed on the oil filtration system.

For more information, pls contact us: [email protected], Whatsapp/Mob: +86-15223801122