Description

DVTP-M Mobile Transformer Oil Purification Machine

Equip with mobile trailer and metallic doors, outside operating in Any where, any place.

Application

DVTP-M Trolley mobile transformer oil purification machine is widely used in electric power, petroleum, chemical industry, and railway, etc. It can purify oil in fieldwork with additional installation of a trailer, a damping spring steel plate, a brake, and a cornering lamp, this guarantees safety and reliability when moving in fieldwork.

It is also used for hot oil circulation drying and oil purification when various large transformer equipment installation and maintenance. Purifying insulating oil in 110KV-500KV transformer, also suitable for high-grade new oil, imported oil deep purifying..

Features

1.Mobile transformer oil purification is used in the electric power system (110kV~500KV).

2.The unit can be used for the transformer vacuum oiling and for various wet electrical equipment vacuum drying.

3.It is humanization design with low noise,deep purification and long time free maintenance to save cost from the running process.

4.On-line measuring and recording of process parameters.

5.It is equipped with leakage and overload stop devices to protect the motor

6.An advanced fully automatic temperature controlling system,liquid-level controlling system,defoaming controlling system,pressure protecting system and excellent configuration can ensure operation of the equipment with high performance

7.Lower maintenance and replacement expense

8.Precision oil pumps have low noise and environmental regulatory compliance will be well met.

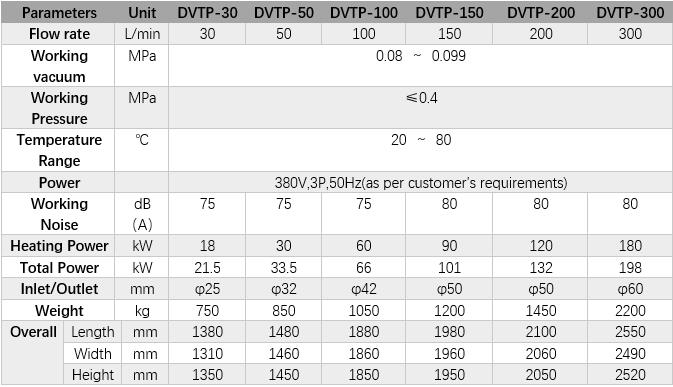

Mobile Transformer Oil Purification's Technical Parameters

| Parameters | Unit | DVTP-M-30 | DVTP-M-50 | DVTP-M-100 | DVTP-M-150 | DVTP-M-200 | DVTP-M-250 | DVTP-M-300 | |

| Flow rate | L/min | 30 | 50 | 100 | 150 | 200 | 250 | 300 | |

| Working vacuum | MPa | 0.08 ~ 0.099 | |||||||

| Working Pressure | MPa | ≤0.3 | |||||||

| Temperature Range | ℃ | 20 ~ 80 | |||||||

| Power | Three Phase 50HZ380V(as per the customer’s requirements) | ||||||||

| Working Noise | dB(A) | 75 | 75 | 75 | 80 | 80 | 80 | 80 | |

| Heating Power | kW | 30 | 30 | 45 | 60 | 75 | 90 | 120 | |

| Total Power | kW | 35.5 | 37.5 | 52.5 | 71.4 | 86.5 | 102.5 | 135 | |

| Inlet/Outlet | mm | φ25 | φ32 | φ42 | φ50 | φ50 | φ60 | φ60 | |

| Weight | kg | 600 | 800 | 1050 | 1400 | 1800 | 2000 | 2200 | |

| Overall | Length | mm | 1050 | 1100 | 1200 | 1450 | 1600 | 1800 | 1900 |

| Width | mm | 750 | 800 | 950 | 950 | 1100 | 1200 | 1200 | |

| Height | mm | 1350 | 1400 | 1500 | 1650 | 1800 | 1900 | 1900 | |

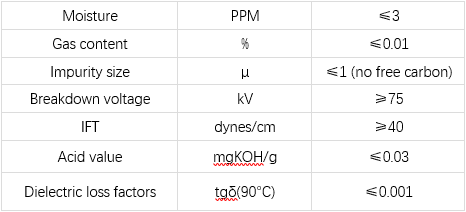

After treatment

| Moisture | PPM | ≤3 |

| Gas content | % | ≤0.01 |

| Impurity size | μ | ≤1 (no free carbon) |

| Breakdown voltage | kV | ≥75 |

| IFT | dynes/cm | ≥40 |

| Acid value | mgKOH/g | ≤0.03 |

| Dielectric loss factors | tgδ(90°C) | ≤0.001 |

Our Service

ASSEN warrants the plant supplied under this specification against defects in material and workmanship under normal use and service for a period of twenty-six (26) months from the date of shipment or twenty-four (24) months after the start-up of the system. ASSEN’s obligation under this warranty is limited to repairing or furnishing, a similar part to replace any part, which was proven to be defective within the warranty period.

1. We customize the machine to your requirements.

2. We have more than 20 years of export experience.

3. We offer our customers high-quality products at a competitive price.

4. We offer our customers excellent after-sales service.

5. We are not satisfied until our customers are satisfied.