The turbine oil system use to provide sufficient, high-quality lubricating oil for each bearing of the turbine unit, adjustment system, jacking device, and the cranking device when the unit is cranking. Therefore, turbine oil quality is an important indicator that affects the safe operation of turbine units. It requires that the turbine oil must be high quality, homogeneous refined mineral oil, and coated with anti-corrosion and anti-oxidation ingredients. In addition, the oil must not contain any harmful impurities that affect performance.

The usage of turbine lube oil purifier machine

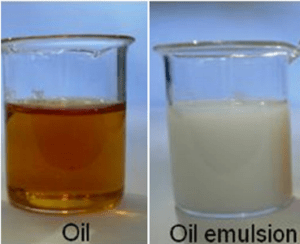

Turbine oil emulsification will cause corrosion of the oil system and rust of unit components. At the same time, the turbine oil will also lose its lubrication, heat dissipation and speed regulation functions, which will seriously affect the safe operation. There are three general reasons for the emulsification of turbine oil: moisture, emulsifier and high-speed mixing. Among them, moisture is an important cause of oil emulsification.

In the operation of the turbine unit, the main reasons for the water ingress in the turbine oil system are due to the lack of tight shaft seals, gas seal leakage, poor lubricating oil quality, and insufficient vacuum in the bearing housing. In addition, the installation and operation of the unit have not met the cleanliness requirements of the equipment, and the presence of dirt and impurities will also affect the quality of the turbine oil.

The emulsification of turbine oil has serious consequences for the operation of the unit. In order to ensure the design, manufacture, installation, operation and maintenance of steam turbine equipment, it is very important to prevent and eliminate water come into the turbine oil system and prevent turbine oil emulsification. Therefore, the following points are the solutions:

(1).Unreasonable design and product manufacturing that does not meet the design requirements will directly lead to water ingress into the turbine oil system.

TY High Vacuum Turbine Lube Oil Purifier

(2). The Turbine Lube Oil Purifier Plant should work together with the running turbo unit.it can carry out oil-water separation and impurity filtration in time. At the same time, oil system components must be clean, sealed, and meet cleanliness standards during manufacturing, installation, and operation.

(3). Turbine oil must meet the technical indicators specified in the national standard GB11120-89, especially the demulsification performance and acid value indicators. Turbine oil should be sampled and checked regularly in accordance with “L-TSA Turbine Oil Change Index SH/T0636-1996”.

(4). For the emulsified turbine oil, we can also add a demulsifier to the oil according to the situation to improve the demulsification performance of the turbine oil. The demulsifier is used to destroy the emulsified film on the oil-water interface and release the water to achieve the purpose of water removal.

Turbine Oil Lube Purifier Service is an extremely important and integral part of the performance of a turbine and the lubricant system. ASSEN has professional service equipment to clean the system of water contamination. If you have requirements, please don’t hesitate to contact us. Tel: +86-2388703683, Email: [email protected]